Journal article

EVA/starch/POE Composite for Footwear Material: How the Chemical Composition Affects Its Properties Compared to Standards

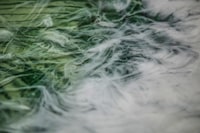

The usage of biodegradable foam material in footwear components has positive impacts on environmental sustainability when disposed into landfills. This study was aimed to investigate the effects of polyolefin elastomer (POE) on its properties of foamed EVA/cassava starch composites compared to standards. Foamed EVA/cassava starch composites were prepared by mixing EVA, cassava starch, and additives using a two-roll mill laboratory scale. Content of POE was varied 10-20 phr. The ratios of EVA/cassava starch were varied from 90/10; 80/20; 70/30; and 60/40. Effects of POE were characterized its density, tensile properties, tear strength, permanent set, abrasion resistance, flex resistance, morphology, and biodegradability. It was found that the increase of POE content in EVA/starch composites increased the density and abrassion resistance, but decreased the tensile strength, elongation at break, and permanent set properties. The best formula of foamed EVA/cassava starch/POE composites for footwear materials contains EVA 80 phr, starch 20 phr and POE 20 phr with density 0.983 g/cm³, tensile strength 22.27 kg/ cm², elongation at break 645.67%, tear strength 9.42 N/mm, volume loss 88.907 mm, no crack when flexed 150 kcs. These results met the requirements of SNI 0778:2009-Sol Karet Cetak for quality classifcation 3 of outsoles. The foamed composite containing POE20 has denser morphology than POE10, while the addition of POE has no signifcance in weight loss after burial test